Initial Situation

Wastewater treatment using stripper columns. The current system has reached its capacity limit concerning flow rate and thresholds.

The Task

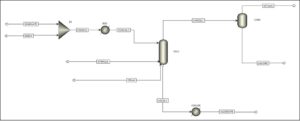

Design a new column including an evaporator and a refeed system to increase the capacity by 30% taking into account the wastewater streams of additional plants.

Project Management

Modelling

- Adapting data of substances for the real system (chemical and physical properties).

- Conducting sensitivity analyses using different components in the column based on former laboratory and process data.

- Identifying the parameters that influence the performance of the system the most.

Insights

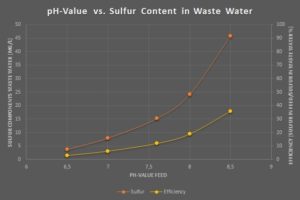

- pH-value of the induced wastewater shows significant impact on the threshold.

- Heavy fluctuations dependent on the chronological discharge of wastewater from different plants.

- Under ideal conditions (concerning pH-value) there are spare capacities in the existing system.

Design Proposal

- Expand the puffer tank in front of the column to equally distribute the feed.

- Install an acid metering to adjust the pH-value.

- Enlarge the column evaporator to allow for an increased capacity.

- The hydraulic system of the column is working on ideal terms even at an increased capacity of 30%.

- The refeed system (condenser, container, pump, valve) is suitable for an increased flow rate, if the pH-value is controlled.